Description

Product Description

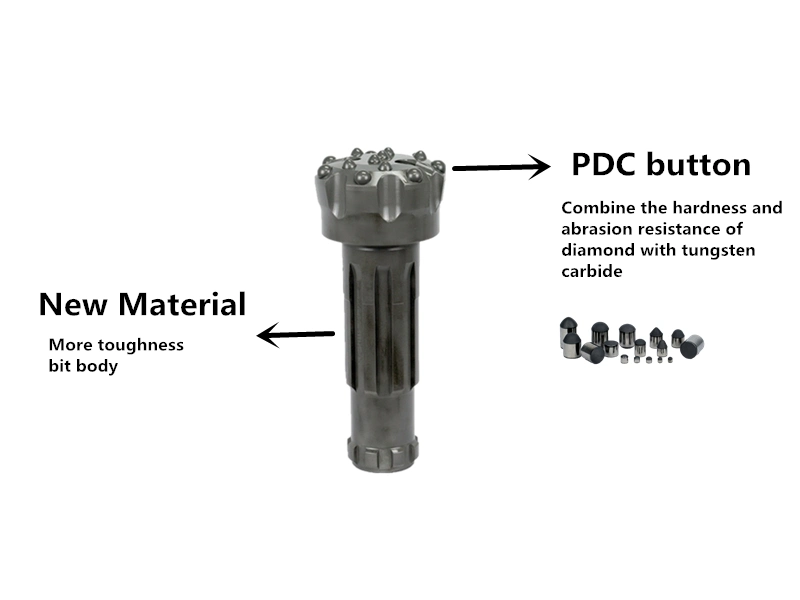

PDC down-the-hole drill bits are made by inserting PDC alloy into the down-the-hole drill bits, replacing carbide with PDC to increase the life of the down-the-hole drill bits.

PDC down-the-hole drill bits are mainly used for very hard rocks and have a lifespan 5-6 times longer than ordinary down-the-hole drill bits.

Place of Origin: Wuhan, China

Brand Name: SUPERDRILL

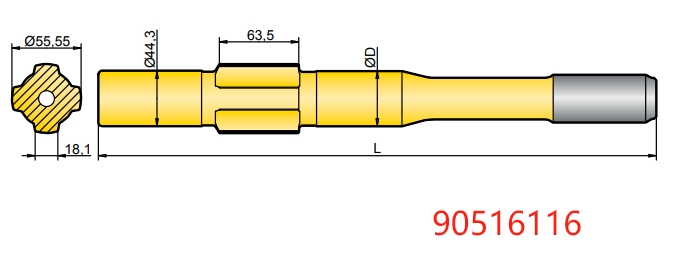

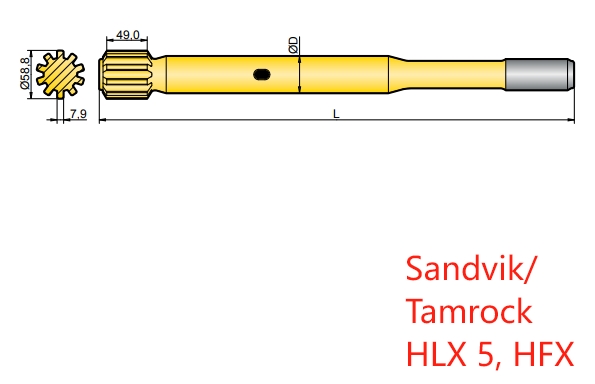

Model Number: DTH hammer SD/BR/COP/DHD/QL/Misson

Advantages:

1.In the case of very hard rock or very bad geological environment, our PDC down-the-hole drill bits are very advantageous. Ordinary carbide drill bits may only drill a few meters to a hundred meters, while the life of our PDC down-the-hole drill bits is 10-30 times that of ordinary carbide drill bits.

2.Higher efficiency than ordinary alloy drill bits.

3.More economical than ordinary alloy drill bits, reducing drilling rig downtime, reducing drill bit replacement time, reducing drill bit grinding, etc.

4.Improve the service life of drilling rig equipment. Reduce equipment loss.

Delivery Time:

Delivery within 2 weeks after payment.

Shipping method:

Air or sea transportation is acceptable

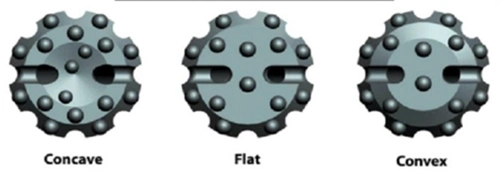

PDC tooth selection

Spherical PDC button, gauge button, suitable for very hard rock.

Ballistic PDC button, front button, suitable for meduim abrasive, medium hard rock.

Parabolic PDC button, front button, gauge button, suitable for meidum abrasive, hard rock.

Flat PDC button, guage protection.

Mobile:

Mobile: E-mail:

E-mail: