When it comes to non-explosive rock and concrete splitting, both the darda c12 and Piston Rock Splitters are popular hydraulic tools. But how do you choose the right one for your project? This article compares their features, advantages, and best use cases to help you make an informed decision.

1. Overview

| Feature | Darda C12 Rock Splitter | Piston Rock Splitter |

|---|---|---|

| Splitting Force | Up to 413 tons | Generally higher; varies by model, often >500 t |

| Drill Hole Diameter | 45–48 mm | 90–150 mm |

| Portability | Handheld, approx. 32 kg | Usually larger and heavier; some handheld types, many mountable on excavators |

| Best For | Small to medium blocks, confined spaces | Large blocks, heavy-duty rock and concrete |

| Operation Noise | Very low, almost silent | Low to moderate depending on size |

| Precision | High (close hole spacing possible) | Moderate (holes spaced further apart) |

| Maintenance | Simple, low maintenance | More complex; depends on model |

| Cost | Higher initial cost, premium quality | Range from economical to high-end |

2. Detailed Comparison

Darda C12 Rock Splitter

Design: Compact and lightweight for easy maneuvering in confined or urban environments.

Application: Ideal for precise splitting in quarries, tunnels, and demolition where vibration and noise must be minimized.

Operation: Requires smaller drill holes (45–48 mm), allowing closer hole spacing and fine control of split lines.

Advantages: Highly portable, low noise, low vibration, safe for sensitive sites.

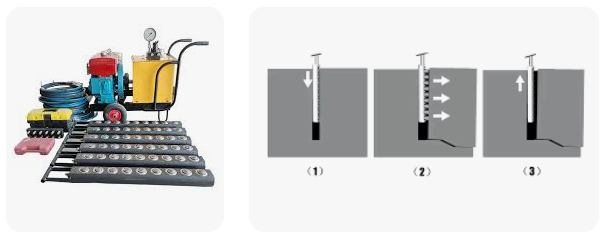

Piston Rock Splitter

Design: Utilizes one or more hydraulic pistons inside larger diameter drill holes.

Application: Suitable for large-scale rock and concrete demolition, foundation removal, and tunneling.

Operation: Larger drill holes (90–150 mm) reduce the number of holes needed but require heavier equipment.

Advantages: Much higher splitting force per wedge, efficient for big rocks and tough concrete, compatible with excavator-mounted systems.

3. Which One Should You Choose?

| Scenario | Recommended Rock Splitter |

|---|---|

| Urban demolition or tight space | Darda C12 |

| Quarry block splitting | Darda C12 or Piston Splitter (depending on block size) |

| Large foundation or tunnel work | Piston Rock Splitter |

| Projects requiring high portability | Darda C12 |

| Heavy-duty mass rock breaking | Piston Rock Splitter |

4. Pricing & Availability

Darda C12: Premium German-made tool, prices typically range from USD 4,000 to 15,000 depending on configuration.

Piston Rock Splitter: Wide price range; economical Chinese models start from around USD 3,000, while larger, advanced models cost significantly more.

5. Conclusion

Both the Darda C12 and Piston Rock Splitters have their unique strengths. If your project requires precision, portability, and low noise, the Darda C12 is the go-to choice. For heavy-duty, large-scale rock breaking, the piston splitter offers unmatched power and efficiency.

Choosing the right splitter depends on your specific application, rock size, working environment, and budget. Contact us to discuss which option fits your needs best!

Mobile:

Mobile: E-mail:

E-mail: