Description

CO2RockBlasting:ASafeandGreen AlternativetoConventionalExplosives

CO2 ROCK BLASTING is a sustainable and eco-friendly alternative to conventional explosives. This method uses liquid carbon dioxide to fracture and break up rock formations, without producing harmful fumes or dangerous byproducts. With CO2 rock blasting, you get a safe and efficient way of rock excavation that doesn't cause harm to the environment. Learn more about the benefits of green blasting and how it can help your project today!

This is an advanced method used for Rock Cracking. Co2 Fracturing Cylinders are filled with liquid Co2 gas and is the primary element used for cracking the rock. This method is extremely safe and convenient as there are no explosives, harmful chemicals or large moving parts or debris. The principle applied in this system is that of Co2 Gas Expansion.

- No Explosives, No Hazardous Chemicals or Fumes.

- No Fly Rock.

- No Vibrations.

- No need of heavy equipment's like Excavators, Rock Breakers or Trenchers.

- No Pollution or EMISSION of Dust.

- Logistics Minimized as various machineries and items can be avoided.

- No major electric supply or related Danger.

- Easy and Quick to Operate.

- High Yield of materials when compared with conventional Machinery.

-

The principle of expansion cracking rock technology of carbon dioxide(rock demolition process)

-

-

The principle of expansion cracking rock technology of carbon dioxide is to use the principle of rapid gasification and expansion under the condition of sudden rapid heating of liquid carbon dioxide, and to generate strong impact force. Through proper control, the rock breaking effect is caused. Specifically, first, the liquid carbon dioxide is charged into the expansion tube by using a filling machine (and a rupture piece, an activator, etc.), and the expansion tube is placed in the blast hole, and the blast hole is tightly sealed; then the igniter is used for activating the activator inside the expansion tube to rapidly expand the liquid carbon dioxide by 1000-2000 times under rapid heating conditions. The strong impact force (200-400 Mpa) first breaks through the rupture piece and then quickly moves along the set vent hole. After rushing out, due to the closed hole, it cannot be freely leaked, thus causing expansion shock to the surrounding rock, causing cracking effect and forming rock breaking effect (as shown in Figure 1)

-

The composition and basic operation steps of expansion cracking rock technology of carbon dioxide

Ⅰ) System composition

The open-air carbon dioxide expansion rock technology consists of ground-operated equipment.

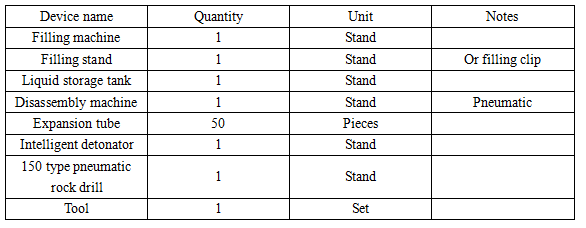

Equipment configuration see attached table 2

Schedule 2 Equipment Configuration Table

1 Ground operation room and equipment

The equipment in the ground operation room is: carbon dioxide liquid storage tank, filling machine, filling station, disassembling machine, etc., as shown in Figure 2.

Mobile:

Mobile: E-mail:

E-mail: